Plasma Cutter

Cutting steel like butter

A common challenge when working with metals is the difficulty of cutting them. Angle grinders are typically used, but what if we could cut steel using extremely hot air instead?

This project is based on a plasma cutter — a device capable of cutting through steel using only electricity and compressed air. All you need is a power outlet and an air compressor to make it work.

Specifications

–Power consumption: 4 kVA

–Maximum current: 15 A

–Required airflow: 50 l/min

–Steel cutting thickness: 5 mm

–Duty cycle: 60%

Cutting with air and eletricity

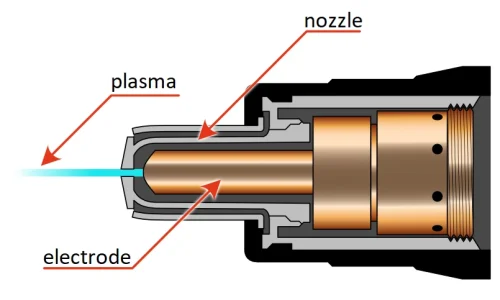

The cutting process of a plasma cutter is very straightforward — the effect is purely thermal. A power supply creates a controlled short circuit of around 40 A at a voltage between 100–400 V. This generates an electric arc that ionizes the air, reaching temperatures of several thousand degrees. When this plasma is directed through a nozzle using compressed air, it produces a stream of extremely hot, ionized air capable of cutting through steel.

Construction from scatch

The main challenge of this project is generating the controlled short circuit needed to ionize the air. The key lies in managing how much current flows through the short circuit. The circuit is based on a full-bridge AC-DC rectifier followed by a filter composed of a 3300 µF, 400 V capacitor. This filter includes a pre-charge circuit to prevent upstream protections from tripping at the connection point.

With the DC supply in place, we obtain an approximate voltage of 325 V, which corresponds to the peak of the sine wave. If a direct short circuit were applied at the rectifier terminals, the resulting current would reach hundreds of amps, potentially damaging the entire system. To limit this, a series resistor is used.

This resistor has a low resistance but a very high power dissipation capacity. The simplest solution was to use two 2000 W electric heating plates in parallel, resulting in a series resistance of 18 ohms.

This way, when the short circuit occurs during cutting, a current of 15 A is generated, which, driven by the compressor, ionizes the air and cuts through the steel.

Air system and ignition

Since this project was built on a low budget using recycled materials, the compressed air system had to follow the same philosophy. A refrigerator compressor was used to supply air to the torch and direct the plasma. These compressors provide an airflow of around 50 l/min and can reach high pressures, although in this case, 2 bar was enough.

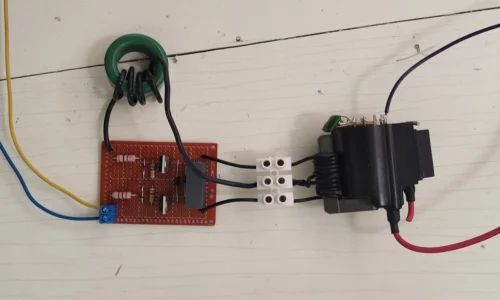

During initial testing, we noticed that starting the electric arc was difficult — sometimes it wouldn’t ignite, or it would extinguish quickly. To solve this, a high-voltage arc pilot circuit was built using a ZVS driver and a flyback transformer from an old TV.

This circuit generates a 20 kV, low-current arc between the torch and the cutting surface. It slightly ionizes the air, making it easier for the main power circuit to start operating reliably.

Metal enclosure and cooling

The entire system was designed with a modular approach. Cooling played a key role, so a metal enclosure with direct air extraction was built. Initial tests showed that the heating elements reached very high temperatures, peaking at around 150°C, which made efficient cooling essential.

Test and Results

After many revisions and improvements, a fully functional plasma cutter was successfully built at an extremely low cost, thanks to the use of mostly recycled components.

The system can cut steel up to 5 mm thick using a nominal current of 15 A at the rectifier, which is quite impressive for a homemade setup.

This project has been essential for enabling other builds that required cutting circles or small parts — tasks that would have been nearly impossible with a standard angle grinder.