Waste Gasifier

Waste to energy

This project started as an idea between a couple of friends. Waste is a major global problem, thousands of tons of garbage are discarded every year in every country, leading to serious environmental and pollution issues.

In some regions, waste is incinerated to generate electricity, in other words, you’re giving away energy through your trash, and in some cases, even paying for it.

Our idea takes this concept further. We convert virtually any type of waste into syngas (synthesis gas), a fuel with a calorific value approximately 30% lower than methane or butane, yet still powerful enough to support efficient combustion. This approach offers a sustainable, innovative way to recover energy from waste and reduce environmental impact.

Specifications

– All kinds of waste excluding metals and glass

– Maximum of 30l of waste

– Low emissions

What is gasification ?

Gasification is a thermochemical process in which carbon-based materials such as plastics, organic matter, or biomass are converted into a combustible gas. This transformation occurs in the presence of a gasifying agent like air, oxygen, or steam. The composition of the resulting syngas (synthesis gas) can vary, but it primarily consists of hydrogen (H₂), methane (CH₄), and carbon monoxide (CO). This gas has a high calorific value, making it an efficient fuel source for power generation, heating, or industrial applications.

Our solution to waste problem

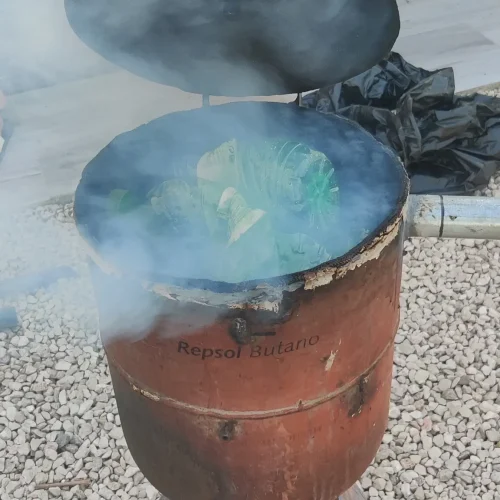

To address the growing waste problem, we have developed a portable gasifier that can be safely installed and operated in a residential setting. The system is composed of two interconnected metal chambers. In the lower chamber, complete combustion takes place using a controlled excess of oxygen, supplied by a fan that injects air. Meanwhile, the upper chamber remains sealed, allowing a low-oxygen environment where gasification occurs. This process generates syngas from the thermal breakdown of waste.

As the waste in the upper chamber decomposes and reduces in mass and volume, it gradually falls into the lower chamber. There, it is fully combusted, leaving only ash. This two-stage system dramatically improves thermal efficiency, as the heat from the combustion zone is reused to drive the gasification process above. From an environmental standpoint, emissions are significantly lower than in traditional single-stage incineration systems, thanks to the controlled, staged combustion and gasification process.

Syngas and results

After extensive testing, including numerous sealing checks and oxygen intake adjustments, we achieved an optimal operating point. At this stage, waste undergoes efficient gasification followed by combustion, resulting in the production of substantial amounts of syngas.

One of the main challenges with raw syngas is its high temperature and impurity levels. To improve its quality and usability, we added a water-cooled extension at the gasifier outlet to lower the temperature of the gas.

With this upgrade, it became possible to burn the syngas directly at the output with a stable flame. In further tests, we successfully powered a 49cc engine using only syngas and air—without the need for gasoline or a filtration system.